Feel free to reach out with any inquiries regarding your project, or send us a non-binding request directly.

Email: info@machinebuilding.cz

Phone: +420 732 128 164

Address:

Machine Building s.r.o.

Tanvaldská 345

463 11 Liberec - Vratislavice nad Nisou

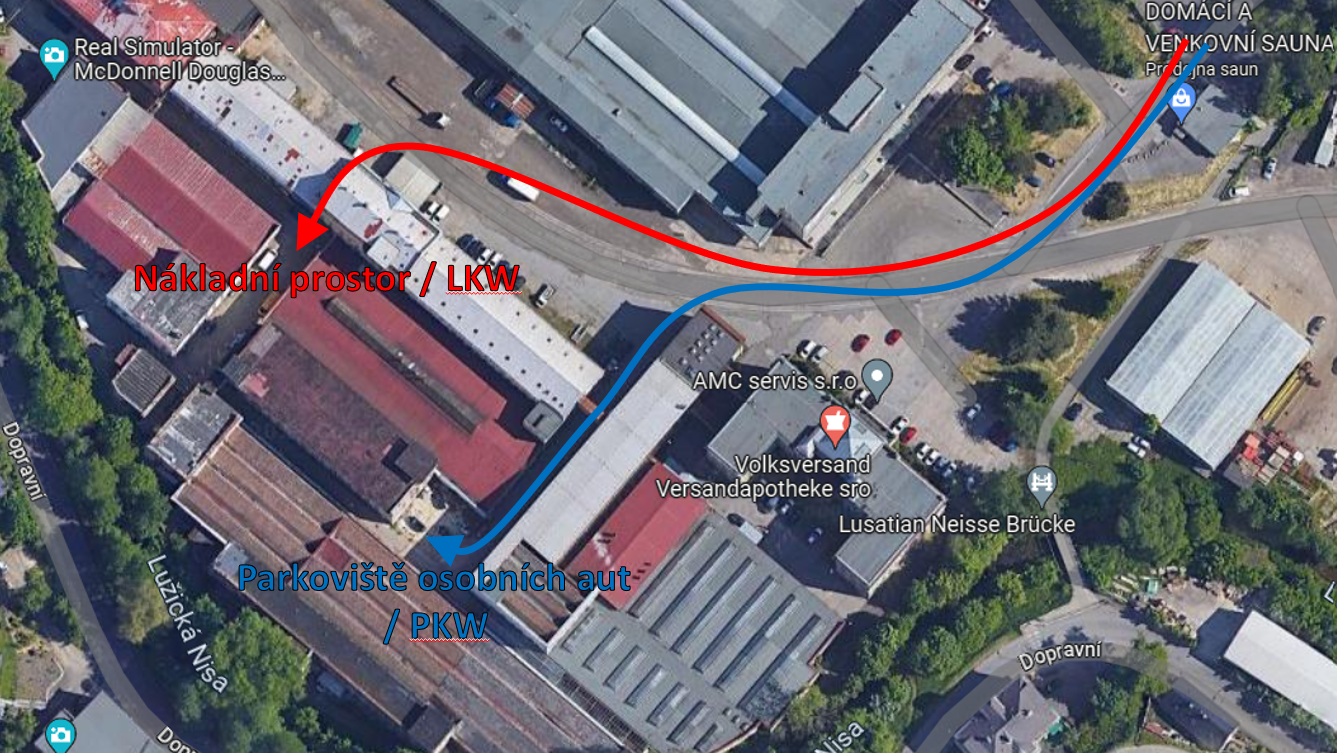

Located in the Intex complex - Building 6b

GPS for passenger cars: 50.74168941804339, 15.087883887070516

GPS for freight trucks: 50.742205576873936, 15.08743477523815

Company Information

Business ID (IČO): 22800891

VAT ID (DIČ): CZ22800891

Bank Account: 276644202/0300

General Terms and Conditions:

About Us

Delivering High-Quality Solutions at Reasonable Prices

Machine Building s.r.o. specializes in robotics and automation. We have our own facilities for welding, machining, and assembly, complemented by a design office for mechanical and electrical engineering. Our programming team focuses on PLC systems such as Mitsubishi, Siemens, and robotic systems from ABB, FANUC, and STAUBLI.

Our goal is to build strong customer relationships by thoroughly understanding their needs and continuously improving our services, delivery speed, and product quality.

Company Milestones

2010: Founded by Mikuláš Hrstka as a design office for custom mechanisms. Initial success in small machines, conveyors, and welded structures for the automotive industry.

2012: Machine Building s.r.o. was established with its first employees and a 200m² facility in Kateřinky. Completed first robotic workstations and complex automation systems.

2014: Annual revenue exceeded CZK 30 million.

2016: Grew to a mid-sized company with ~25 employees and dozens of installed applications annually. Acquired a 6000m² facility with a 2000m² production area and office space. Expanded installations across Europe (Germany, France, Spain, Russia, Denmark).

2017: Revenue surpassed CZK 50 million.

2018: Developed steel-belt conveyor systems for heavy loads and custom production management software. Surpassed 10 robotic applications installed annually.

2019: Introduced modular automation structures and robotic docking systems. Company expanded to 35+ employees.

2020: Shifted focus away from the automotive industry, introduced DIY conveyor and automation design applications, and opened the Industrial Robotics Center.

2021: Faced significant challenges due to the pandemic, resulting in an 80% revenue drop. Downsized and sold company headquarters to sustain operations.

2022: Despite challenges from the war in Ukraine and material price instability, collaboration with long-term suppliers helped stabilize operations.

2023: Successfully diversified into new industries (electronics, chemicals, construction). Proprietary systems contributed significantly to revenue, marking a return to profitability after two difficult years.

Industry-Specific Websites