Industrial fencing and machine guarding

Modular construction of automated machines is becoming an increasingly popular choice in industrial applications. This technology enables machine manufacturers to efficiently and quickly build complex machinery using pre-designed and customizable modules. This approach helps reduce development and construction costs, shorten production time, and enhance responsiveness to changing customer requirements. Additionally, these modules can be easily replaced or upgraded, ensuring straightforward maintenance and expanded machine functionality. Overall, modular construction of automated machines offers significant advantages in industrial applications and is increasingly adopted in practice.

Innovative and Rapid Construction with a Modular System

Innovative and Rapid Construction with a Modular System

Our modular system is designed to meet the dynamic needs of modern industry. The load-bearing columns of our system feature smart cutouts, allowing panels and fencing infills to be easily inserted. Once in place, everything is securely fastened with a screw, ensuring a strong and stable structure. This intuitive assembly method enables not only rapid machine construction but also quick and easy modifications or adjustments when needed. With this system, you can be confident that our solution is not only efficient but also a highly flexible option for your manufacturing needs.

Cable trays integrated directly into machine enclosures

Cable trays integrated directly into machine enclosures

In today’s industrial era, safety and efficiency are top priorities. With our new modular system for safety enclosures, we have successfully combined these two key aspects. Our innovative solution features safety fencing with integrated cable trays, enhancing both machine and user protection while significantly simplifying cable management and installation. This allows for quick and easy modifications to machine enclosures or robotic setups, ensuring that cable routing is neatly and securely concealed. By integrating cable trays directly into the enclosure, the need for external cable ducts is eliminated, reducing costs and increasing the overall flexibility of the system.

Flexible steel flooring for mobile machines

Flexible steel flooring for mobile machines

As part of our innovative approach to industrial solutions, we have expanded our unique modular system with flexible steel flooring specifically designed for machines with wheels. These floors represent a revolution in machine mobility, allowing users to quickly and easily relocate an entire machine within minutes. And the best part? When stability is required, our flooring offers a simple and secure anchoring system to keep the machine firmly in place. This solution not only enhances workspace flexibility but also delivers significant cost and time savings when reorganizing production lines or adapting manufacturing processes. Our flexible steel flooring is the future of adaptive manufacturing, ensuring seamless adjustments to evolving production needs.

Integrated signaling, lighting, and controls

Integrated signaling, lighting, and controls

Our innovative modular system features integrated lighting and signaling directly within the support columns of the fencing. This allows for clear visual signals to be visible from all angles, enhancing both efficiency and safety in the workplace. Additionally, with the option to install control buttons directly into the columns, we eliminate the need for additional distribution boxes, simplifying the entire installation process. This solution not only saves time and reduces installation costs but also provides a clean, modern aesthetic for machines and robotic production lines.

Module categories – extensions for your individual needs

Our innovative modular system is designed to be as versatile and adaptable as possible for various needs and applications. In addition to basic components, we offer a wide range of accessories that further expand its usability. These include service lights for optimal visibility during operation, various types of infill panels for specific requirements, doors equipped with modern safety locks for maximum protection, as well as bases and fixtures specifically designed for robot installation. All of these options allow users to customize and optimize their workstations according to individual needs and requirements.

Find out more at the following links:

Industrial safety solutions for machines

Although industrial fencing has a wide range of applications, its primary purpose is always the safety of operators. In addition to defining areas where machines are operated or materials are handled, it also protects employees from accidental contact with hazardous zones. Since industrial fencing is often used in high-speed and high-flow environments, it plays a crucial role in preventing accidents and injuries.

Industrial fencing comes in various shapes, sizes, and materials to meet different safety requirements. Choosing the right type of fencing for a specific application is essential to ensuring maximum protection.

Industrial fencing can also be equipped with various components such as gates, locks, and sensors. These elements enhance safety by restricting access to authorized personnel only. Some sensors can be integrated into machine control systems to prevent dangerous situations when machines and people operate in the same area.

Another key advantage of industrial fencing is that it enables easy and efficient machine maintenance. By separating maintenance areas from material handling zones, it not only protects workers from hazards during servicing but also ensures safe and convenient access for technicians.

Additionally, industrial fencing can help define and identify specific areas within industrial facilities, improving overall organization and the flow of materials and personnel.

Our fencing system has undergone extensive development and testing to guarantee durability, stability, and seamless integration of all components. It meets all safety requirements and ranks among the most robust systems available on the market.

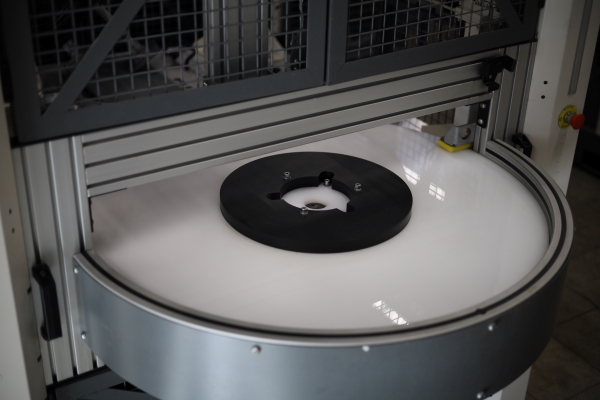

The system includes a wide portfolio of modules—not only fencing panels but also accessories for operator workstations, robotic arm integration, and packaging applications.

Our fencing system is ideal for:

- Robotic applications

- Dedicated-purpose machines

- Production lines