Modern Maintenance

Modern maintenance represents a revolutionary leap forward in leveraging cutting-edge technologies. It involves the use of artificial intelligence (AI) and predictive sensors, enabling companies to anticipate potential issues and machine failures before they occur. This predictive maintenance approach provides real-time, visual insights into equipment performance and status, facilitating preventive maintenance and the optimization of machine operations.

Modern maintenance represents a revolutionary leap forward in leveraging cutting-edge technologies. It involves the use of artificial intelligence (AI) and predictive sensors, enabling companies to anticipate potential issues and machine failures before they occur. This predictive maintenance approach provides real-time, visual insights into equipment performance and status, facilitating preventive maintenance and the optimization of machine operations.

Role of AI in Predictive Maintenance

AI is crucial for collecting and analyzing the large volumes of data generated by sensors. Advanced algorithms identify patterns and relationships that are difficult for humans to detect, allowing for the prediction of possible failures and interventions before a breakdown happens. The results include enhanced equipment reliability, reduced maintenance costs, and extended machine lifecycle.

Predictive Sensor Technology

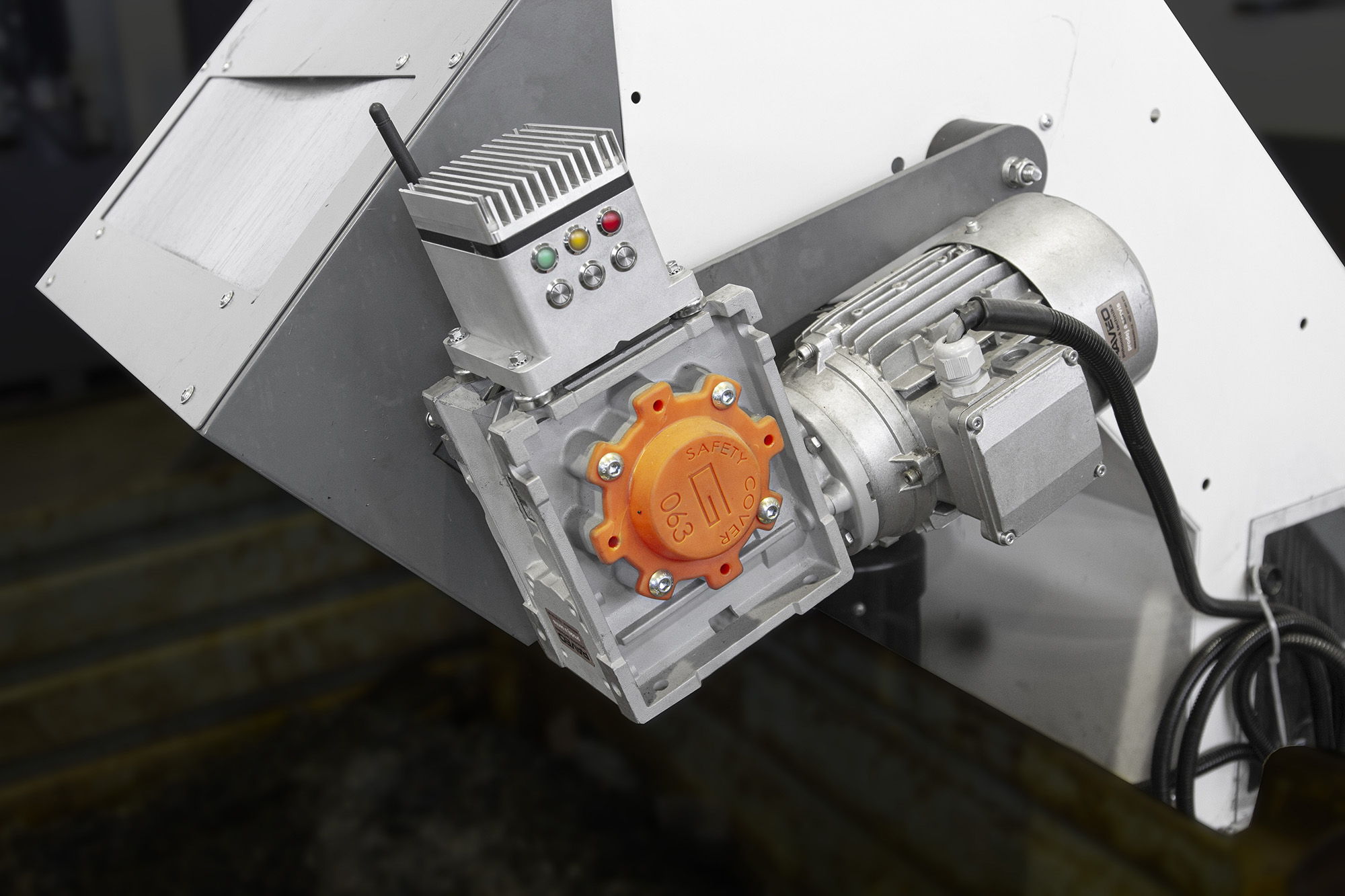

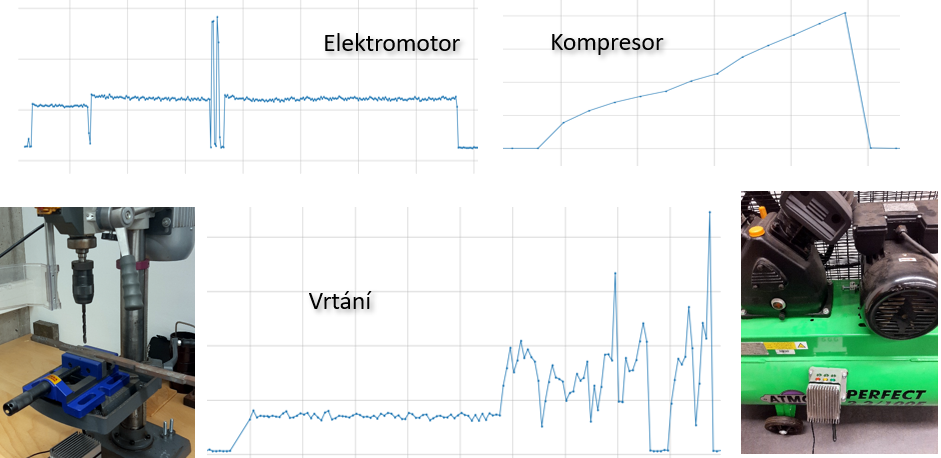

Predictive sensor technology leverages sensors housed in a robust aluminum body to measure vibrations, oscillations, temperature, and sound. These sensors allow you to estimate the condition of equipment and anticipate future failures with an accuracy ranging from several weeks to months. They can work wirelessly or via a physical connection, configured for either periodic data capture at set intervals or continuous monitoring to detect impacts or collisions. This approach helps prevent destructive overloads or failures, thereby reducing downtime and expensive repairs.

Predictive sensor technology leverages sensors housed in a robust aluminum body to measure vibrations, oscillations, temperature, and sound. These sensors allow you to estimate the condition of equipment and anticipate future failures with an accuracy ranging from several weeks to months. They can work wirelessly or via a physical connection, configured for either periodic data capture at set intervals or continuous monitoring to detect impacts or collisions. This approach helps prevent destructive overloads or failures, thereby reducing downtime and expensive repairs.

Key Functions of Predictive Sensors

- Vibration Detection: High-sensitivity sensors identify abnormalities in machine vibrations, preventing damage.

- Oscillation Detection: Recognizes machine oscillations that can indicate upcoming issues.

- Temperature Measurement: Monitors machine temperatures to detect overheating, often due to overload.

- Sound Detection: Tracks mechanical noise, revealing potential mechanical malfunctions.

Long-Term Reliability. By regularly monitoring equipment health, sensors detect early signs of wear or failure, allowing for planned part replacement and repair. This lowers maintenance costs and minimizes unplanned downtime.

Flexibility. Designed for diverse applications across manufacturing lines, facilities, and transport. Various sensor types can target vibrations, temperature, pressure, sound, and more.

Easy Installation. Sensors can often be added without disrupting operations; in some cases they are pre-installed, reducing setup time and costs.

Low Maintenance. When correctly installed and configured, predictive sensors require minimal upkeep for years; battery or unit replacements are quick.

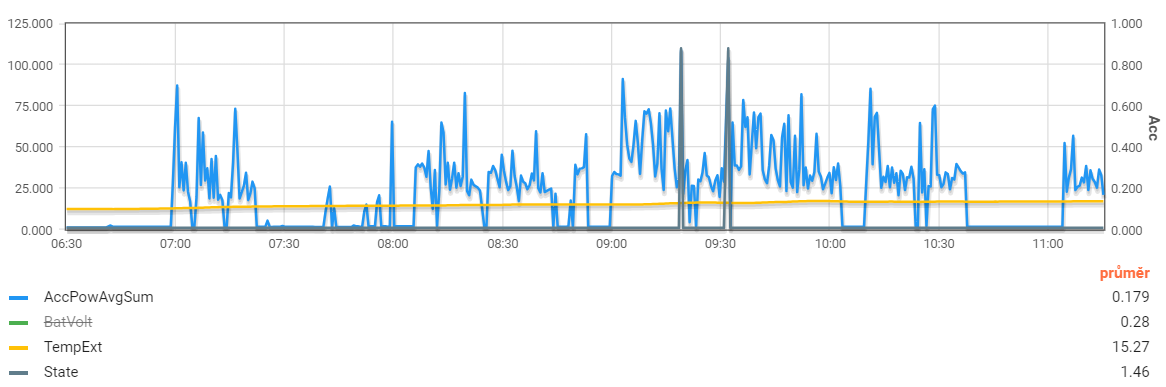

Machine Maintenance & Load Monitoring – Machine Load

A major advantage of predictive sensors is the ability to monitor machine performance in real time. This enables immediate responses to operational changes and early detection of potential failures, minimizing the risk of production losses and boosting reliability.

Monitoring machine load and stress levels is crucial for efficient operation and for preventing overloads. Using predictive sensors, you can accurately measure how hard a machine is working, revealing whether it is running at optimal capacity or under too much strain. These sensors can also integrate with other monitoring systems to track factors such as temperature, vibration, or output volume—creating a highly efficient setup for real-time machine optimization.

CNC Machinery Maintenance

Maintenance of CNC machines is essential for maximizing performance and extending equipment lifespan. By using a predictive sensor, preventive maintenance can be scheduled based on real-time data about machine health, leading to fewer interruptions.

During operation, the predictive sensor gathers data on vibrations, temperatures and other key parameters. Analytics reveal potential issues early so that maintenance can be planned at the optimal time.

Conveyor Maintenance

In conveyor maintenance, predictive sensors continuously track the health of motors, chains, bearings and other parts by detecting vibrations and oscillations. Early anomaly detection prevents failures, reduces repair costs and increases availability. The sensor also monitors motor temperature and can issue alerts or stop the conveyor in case of overheating.

General Machinery and Mechanism Maintenance

For rotational and linear systems, predictive maintenance with sensors enables real-time health checks and early detection of anomalies in bearings, shafts and other critical components. Software turns sensor data into clear outputs and recommendations, minimizing stoppages and extending equipment life.

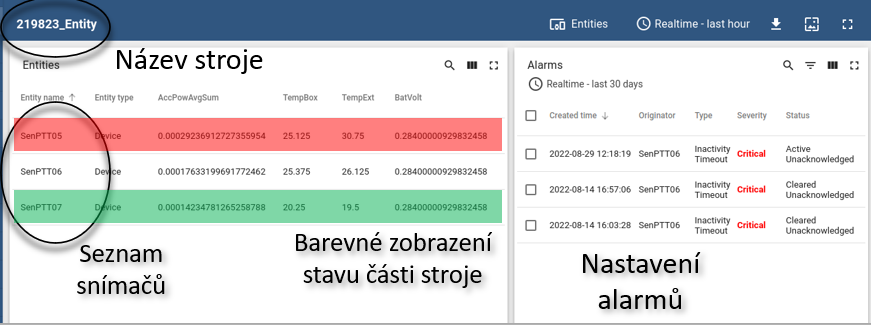

Simplified Readouts for Maintenance and Operations

A user-friendly dashboard gives an at-a-glance overview of sensor states and analytics. Instead of reading raw curves, a simple traffic-light view indicates wear or defects on the monitored mechanism.

Test Drive Predictive Sensor Technology

Our company offers the option to rent predictive sensor technology so that you can evaluate its potential for your specific needs. Contact us to learn how this innovative solution can enhance your industrial processes.

Machine Building is a Solution Provider in the National Centre of Competence – Mechanical Engineering

The National Centre of Competence – Mechanical Engineering (NCKS) focuses on research, development and innovation needed to increase the competitiveness of the Czech engineering industry. The agenda reflects customer and user requirements as well as economic, environmental, social and technological trends, with emphasis on performance, energy efficiency, automation, material savings, environmental impact, process digitization and Industry 4.0.

The NCKS project is co-funded by the Technology Agency of the Czech Republic within the National Centres of Competence Programme and the National Recovery Plan (EU’s Recovery and Resilience Facility).