Spray Technology for Lubrication and Anti-Corrosion Protection

Application of Lubricant and Cutting Emulsion Spraying

In today's industrial world, efficiency and precision play a crucial role. One of the key elements ensuring the smooth operation and long lifespan of machines and equipment is the use of high-quality lubricants and cutting emulsions. Thanks to modern spraying technologies, we can achieve optimal results with minimal material waste. Lubricants and cutting emulsions are essential agents that help reduce friction, cool, and remove contaminants from working surfaces. Proper application of these materials ensures that industrial machines and tools operate smoothly, with extended lifespan and improved efficiency.

Proper application of lubricants and cutting emulsions is key. Modern spraying technologies allow precise application, minimize waste, and ensure smooth and even coating. Some benefits include:

- Precise Application: Enables dosing the material exactly where it is needed, reducing waste and ensuring optimal performance.

- Fast and Efficient: Modern spraying technologies allow for quick and effective application, saving time and costs.

- Environmental and Safety Benefits: Reduces material waste and minimizes worker exposure to potentially harmful substances.

The technology of lubricant and cutting emulsion spraying is used across various industrial sectors, including:

- Metallurgy: For the protection and maintenance of tools and machines processing metals.

- Automotive Industry: Application of lubricants and protective emulsions for durability and long service life of components.

- Engineering: Optimization of the functionality and lifespan of machines and equipment.

Innovative spraying technology for lubricants and cutting emulsions represents a reliable way to enhance efficiency and sustainability in industrial operations. Proper application of these materials is crucial to ensuring long-term success and competitiveness of your business in a dynamically changing industrial environment.

Application of Anti-Corrosion Protection

Corrosion, or "rust," is the nemesis of many materials, especially metallic ones. Unfortunately, it is a process that can significantly shorten the lifespan and quality of products and structures. Thanks to modern technology, we now have access to anti-corrosion sprays that provide long-term protection. Anti-corrosion protection is a process that involves applying a special coating or protective layer to the surface of a material to prevent damage caused by corrosion. Corrosion is a chemical process that leads to the degradation of metals due to environmental influences, typically moisture and salts.

Airless spraying is a coating application method that does not use compressed air. Instead, the coating is applied using a high-pressure pump that forces the material through a specialized nozzle. This technology has several advantages:

- Even Coverage: Airless spraying allows for uniform and smooth surface coverage without splattering or bubble formation.

- Application Speed: This method enables fast and efficient coating application, saving both time and costs.

- Reduced Material Waste: Thanks to precise application, material waste is minimized, making this method both economically and environmentally advantageous.

- Safety and Health: Reduces risks associated with aerosol inhalation and chemical exposure, which are often linked to traditional spraying methods.

Anti-corrosion protection using airless spraying can be utilized in various industries and applications, including:

- Automotive Industry: Protection of vehicle bodies and other components against corrosion.

- Construction: Protection of structural elements, bridges, and other building structures.

- Shipping Industry: Protection of ships and other marine structures from aggressive maritime environments.

- Industrial Machinery and Equipment: Protection of machinery and equipment in industries with high corrosion risks.

In the fight against corrosion, anti-corrosion coatings applied through airless spraying represent a revolutionary solution. Not only do they provide a higher level of protection, but they also enable fast, economical, and safe application. With a growing emphasis on sustainability and environmental protection, this solution integrates the best of both approaches.

Anti-Corrosion Protection CREPEX®

Anti-Corrosion Protection CREPEX®

CREPEX® – a coating material that prevents rust formation through a chemical reaction occurring beneath the coating film, leading to the creation of an anti-corrosion pigment firmly embedded in the substrate, thereby passivating its surface. This combination results in a compact material providing protection against rust formation and stabilizing the ongoing corrosion process, as tested by certified research institutes.

Contemporary research on corrosion formation confirms the instability of iron atoms, where even exposure to sunlight and UV radiation can create conditions that, in the presence of water or a small amount of humidity found in the air, lead to the formation of corrosion (iron oxides – rust). These risks are eliminated by another newly patented anti-corrosion coating material under the trade name CREPEX®UV, based on styrene-acrylate synthetic or water-dispersible resin.

The CREPEX®UV coating contains effective stabilizers that block the effects of sunlight or UV radiation in the presence of anti-corrosion pigments for a certain period (e.g., during maritime transport) even without subsequent coverage with a topcoat or another protective layer. This anti-corrosion coating, acting as a passivation layer, can be applied to both corroded and non-corroded metal surfaces, such as iron, steel, aluminum, zinc, etc., with the same efficiency.

CREPEX®UV is a revolutionary new protection for metal surfaces, suitable for corrosion prevention during transport to the final destination. After assembly or completion of transported metal components such as beams, bridges, building structures, car bodies and chassis, pipelines, railings, ship surfaces, etc., final surface and design treatments will be applied.

In close collaboration with research institutes specializing in material protection, we develop technologies for the application of anti-corrosion coatings and can design a comprehensive coating system that is optimal for various types of materials, whether it be iron, steel, aluminum, copper, or others, based on client requirements for final surface properties.

The combination of CREPEX® UV coating material with the TEMADUR® 10 topcoat (with hardener 7590) from the Finnish manufacturer TIKKURILA® has been tested in a high-corrosion-aggressiveness environment classified as C4 according to ČSN EN ISO 12944-2. The tests confirmed the high durability of the coating system for a period of 15 years or more and its long-term anti-corrosion effectiveness in this environment.

More details about Crepex products can be found here.

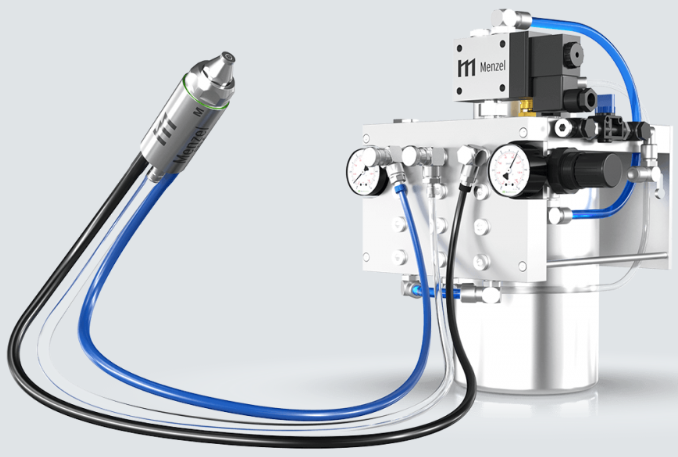

Reliable Coating and Spraying Technology by Menzel Metallchemie

Menzel Metallchemie GmbH is a pioneer and market leader in the development and production of applications with minimal amounts of cooling lubricants (MMKS) and biodegradable cooling lubricants. Through rigorous optimization, we offer comprehensive solutions for demanding tasks in punching, forming, and cutting technologies. Environmentally friendly, cost-reducing, and process-reliable. Modular, flexible, and cost-effective – for your technological advantage over your competitors.

By using our innovative INDUTEC® MS (MMKS) minimal quantity cooling and lubrication systems, you benefit from low media costs, storage, cleaning, and disposal savings, as well as dry workpieces, machines, and chips, and potentially extended tool lifespan.

NOZZLES AND SPRAY HEADS - INDUTEC® MS COAXIAL HEADS

STANDARD EQUIPMENT FOR ALL INDUTEC® MS COAXIAL SPRAY HEADS

STANDARD EQUIPMENT FOR ALL INDUTEC® MS COAXIAL SPRAY HEADS

>> Main body: Stainless steel

>> Coaxial spray head and needle: Stainless steel

>> O-rings: Viton

>> Control air pressure: max. 6 bar - [For lower network pressure, a compression spring for lower control air pressure is optional.]

>> Spray air pressure: max. 6 bar

>> Medium pressure: max. 6 bar

>> Max. Sprayed air volume: approx. 100 l/min.*

* Input pressure (spray air) 6 bar, hose length 1 m

MATERIAL AND AIR FLOW RATES

By adjusting the rotary throttle valves or dampers for the medium, depending on pressure and viscosity, the INDUTEC® MS SD3 and SD4 coaxial spray heads can achieve a medium flow rate from 0 to approximately 340 ml/min continuously.

Depending on the settings of the rotary throttle valves or dampers for spray air, the INDUTEC® MS SD3 & SD4 coaxial spray heads have air flow values ranging from 0 to approximately 100 l/min. Using the INDUTEC® MS coaxial spray head FD4 Z2, a spray air output of approximately 180 l/min can be achieved.

STANDARD DESIGN

All seals that come into contact with the medium are made of fluororubber FPM (trade name Viton) by default.

SPECIAL VERSIONS

When using many other media in the INDUTEC® MS minimal quantity cooling and lubrication system, various sealing materials other than Viton can be used. Suitable seals are available for almost every application.

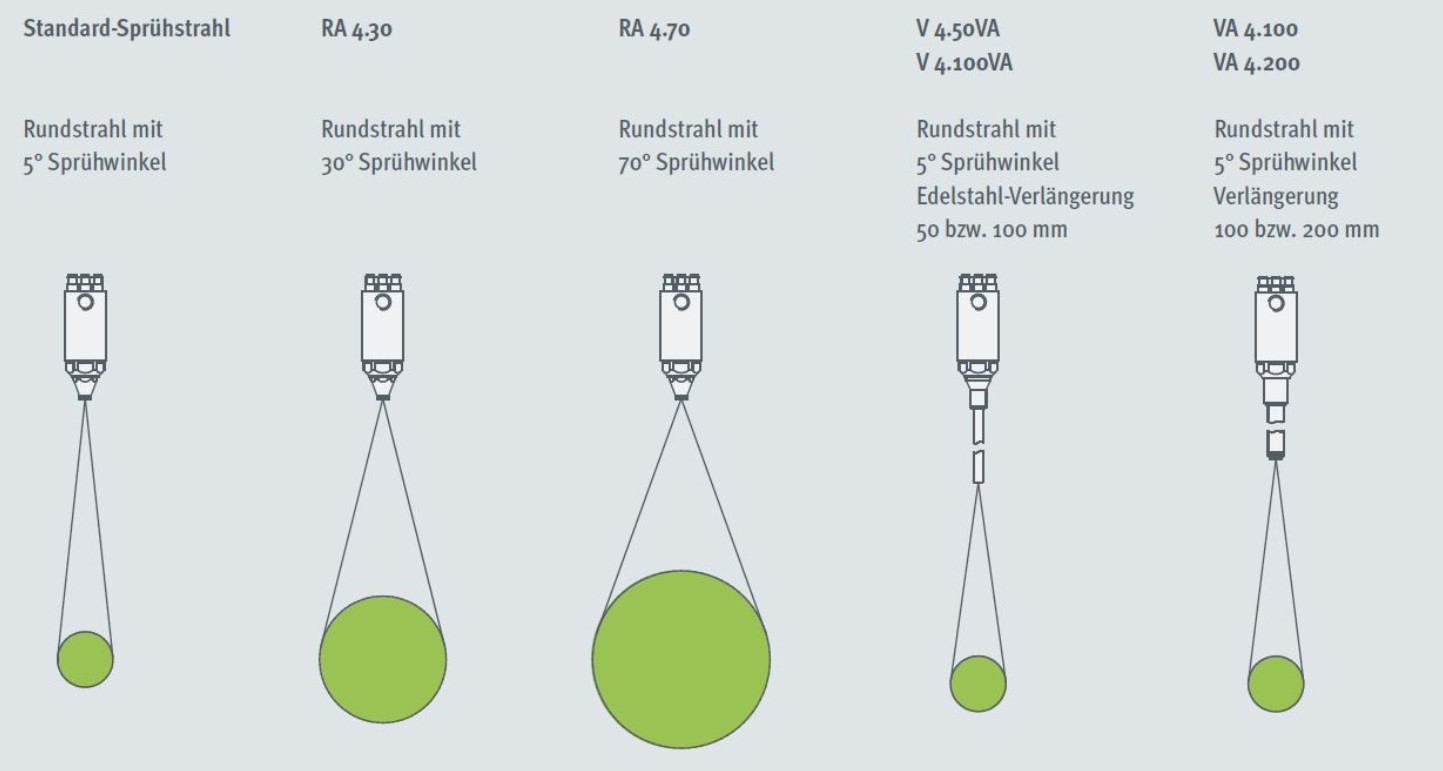

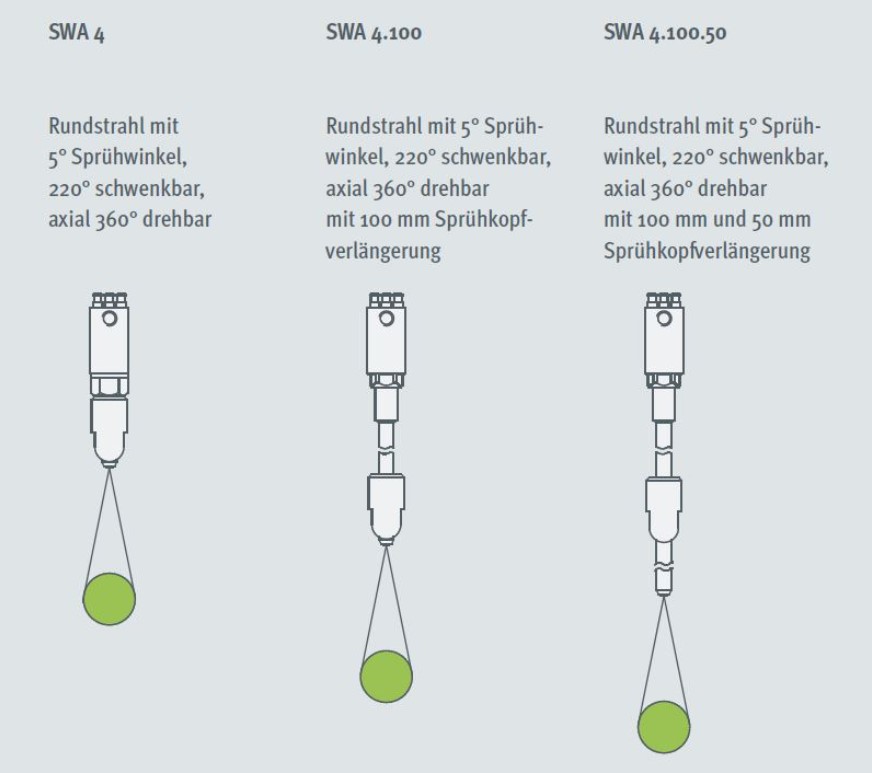

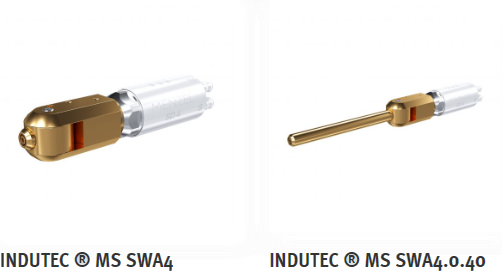

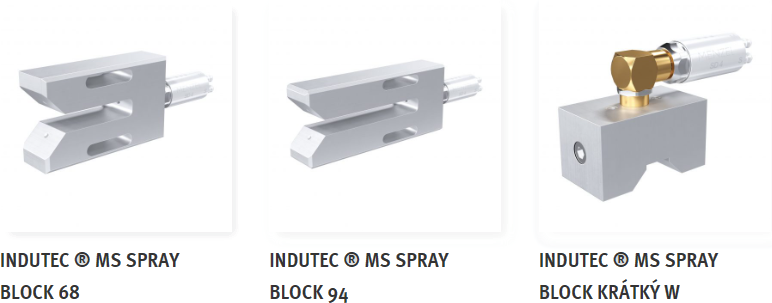

INDUTEC® MS SD represents a nozzle concept that can be used to meet a wide range of requirements. The system is based on a coaxial spray head that generates an omnidirectional stream. Special accessories can be used to create different nozzle shapes and spray angles for almost any application.

Due to their extremely small size, coaxial spray heads require only a small installation space. For hard-to-reach spray locations, they can be extended with an attachment, even in a curved shape.

HOW THE INDUTEC® MS COAXIAL SPRAY HEAD WORKS

Such a coaxial spray head operates pneumatically. It is sealed with a needle that is pressed against the spray opening by a spring. This needle is pushed back by control air pressure, releasing the spray opening. The medium is fed into the coaxial spray head from a separate pressure tank. Spray air is supplied through a third pressure line. This spray air surrounds the medium as it exits the coaxial spray head, forming a precise, directionally stable, and non-misting spray stream.

ALMOST ANYTHING CAN BE SPRAYED

Thanks to continuously adjustable pressure, any medium can be sprayed – from water-mixed cooling lubricants to highly viscous cutting and drawing oils.

EVEN MINIMAL AMOUNTS CAN STILL BE PRECISELY CONTROLLED

Depending on the application, the respective coaxial spray head must be adapted to specific requirements with appropriate modifications.

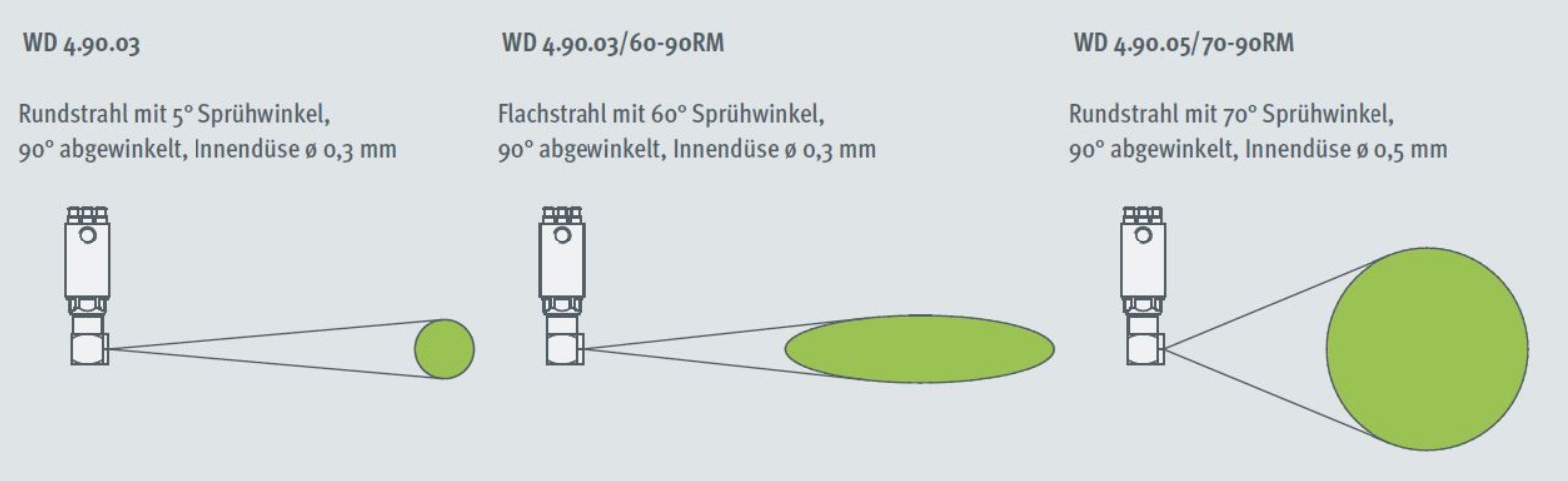

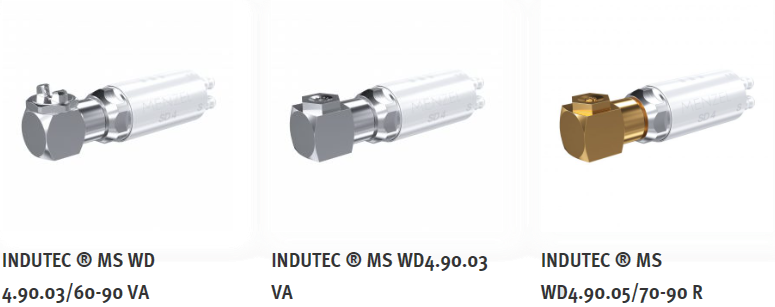

Changing the internal nozzle inserts allows for adjusting the material flow rate. The shape of the spray jet and spray angle can be altered using different attachments.

Theoretically calculated spray angles are approximate values. The decisive factor is always the interaction between the medium and spray air pressure, which must always be in an appropriate ratio. Therefore, practical on-site tests are always recommended to determine precise values.

MODULAR VARIETY

Various module combinations allow for the creation of countless variations of INDUTEC® MS SD3/SD4 coaxial spray heads. This means that an optimal coaxial spray head can be assembled for almost any application.

ROUND SPRAY JET - INDUTEC® MS COAXIAL HEADS

FLAT SPRAY JET - INDUTEC® MS COAXIAL HEADS

The standard spray jet (round spray) can be changed to a flat spray using different attachments.

RING SPRAY JET - INDUTEC® MS COAXIAL SPRAY HEADS

This special attachment can be used, for example, to lubricate the inside of a pipe.

ROTATING ATTACHMENTS - INDUTEC® MS COAXIAL SPRAY HEADS

ANGLED ATTACHMENTS - INDUTEC® MS COAXIAL SPRAY HEADS

If space is limited, angled attachments can be used.

ATTACHMENTS FOR BAND AND CIRCULAR SAWS - INDUTEC® MS COAXIAL SPRAY HEADS

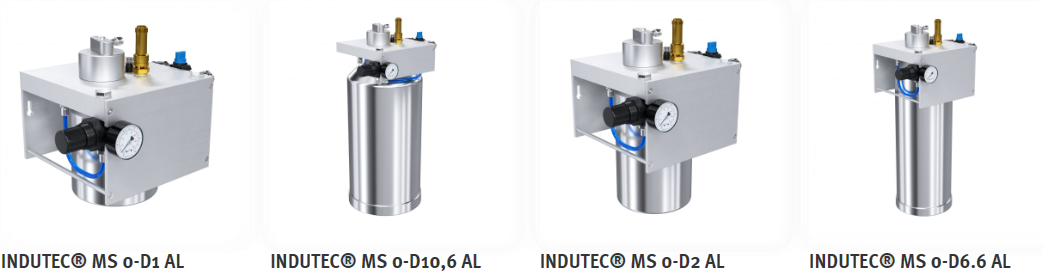

INDUTEC® MS Basic Systems - 1 Spray Cycle

INDUTEC® MS BASIC SYSTEM: READY TO USE IMMEDIATELY

The simplest way to equip an INDUTEC® MS spray station is to use one of the INDUTEC® MS basic systems.

All INDUTEC® MS basic systems operate on the principle of a pressure vessel and can be controlled electro-pneumatically. They already contain all the components required for commissioning without complex installation work.

BASIC SYSTEMS ARE AVAILABLE IN DIFFERENT VERSIONS:

>> For connecting 1 to 4 coaxial spray heads

>> With one or two separate spray cycles

>> With a capacity of 1, 2, or 6 liters

>> With a power supply of 24 V, 110 V, or 230 V

SPRAY CYCLES

In systems with synchronized spray cycles, all connected coaxial heads spray simultaneously. In systems with two separate spray cycles, two groups of coaxial spray heads can be controlled independently.

TWO SOLENOID VALVES FOR EVEN MORE PRECISE CONTROL

Using a second solenoid valve, spray and control air can be regulated separately. This option is available as an optional feature.

HOW TO CHOOSE THE RIGHT SYSTEM FOR YOUR APPLICATION:

>> First, determine the number of required coaxial spray heads.

>> Select an appropriate container size.

>> Then, choose a system that is suitable for your type of power supply.

INDUTEC® MS Basic Systems - 2 Spray Cycles

INDUTEC® MS BASIC SYSTEM: READY TO USE IMMEDIATELY

The simplest way to equip an INDUTEC® MS spray station is to use one of the INDUTEC® MS basic systems.

All INDUTEC® MS basic systems operate on the principle of a pressure vessel and can be controlled electro-pneumatically. They already contain all the components required for commissioning without complex installation work.

BASIC SYSTEMS ARE AVAILABLE IN DIFFERENT VERSIONS:

>> For connecting 1 to 4 coaxial spray heads

>> With one or two separate spray cycles

>> With a capacity of 1, 2, or 6 liters

>> With a power supply of 24 V, 110 V, or 230 V

SPRAY CYCLES

In systems with synchronized spray cycles, all connected coaxial heads spray simultaneously. In systems with two separate spray cycles, two groups of coaxial spray heads can be controlled independently.

TWO SOLENOID VALVES FOR EVEN MORE PRECISE CONTROL

Using a second solenoid valve, spray and control air can be regulated separately. This option is available as an optional feature.

HOW TO CHOOSE THE RIGHT SYSTEM FOR YOUR APPLICATION:

>> First, determine the number of required coaxial spray heads.

>> Select an appropriate container size.

>> Then, choose a system that is suitable for your type of power supply.

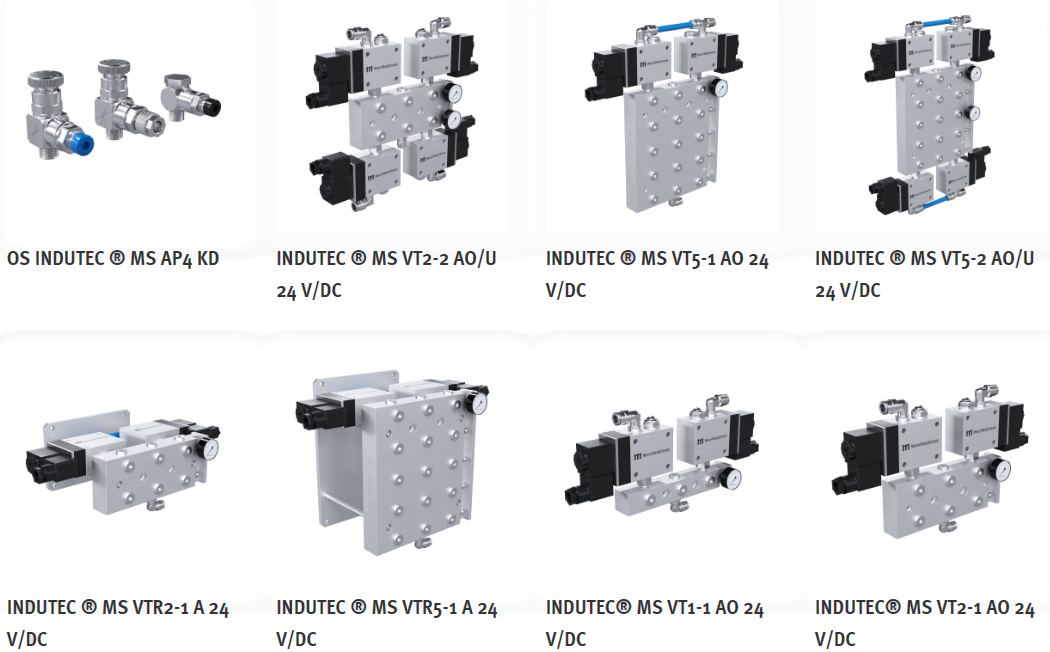

INDUTEC® MS Modular Systems / Valve Units (VT and VTR) for SD4

PRECISE DOSING OF MINIMAL MEDIUM QUANTITIES

The timing and duration of the spraying process can be set on the valve unit. Regarding the power supply type, you can choose between versions with 24V, 110V, and 230V.

MODULARLY EXPANDABLE

To supply multiple spray locations, a large number of valve units can be connected in parallel to the pressure vessel, and each spray station can be individually equipped with one or more coaxial spray heads.

PLACEMENT

Valve units can be placed anywhere. Connection kits and coaxial spray heads must be assembled separately and individually.

ELECTROMAGNETIC VALVES (M07)

3/2-way solenoid valve, electrically controlled

Connection G1/4"

Working pressure 1.5 ... 10 bar

Temperature range -10°C – +70°C

Operating voltage 24V DC or 230VAC

Power consumption 4.2W at 24VDC or 7.4VA at 230VAC

Seals: NBR and POM

VALVE UNITS FOR INDUTEC® MS COAXIAL SPRAY HEADS

The INDUTEC® MS system offers valve units for connecting one, two, or up to five spray heads.

Various versions are available for different spray cycle requirements, media channels, and additional adjustment options.

For installation locations with limited space, valve assemblies are also available in a compact design without a rear panel.

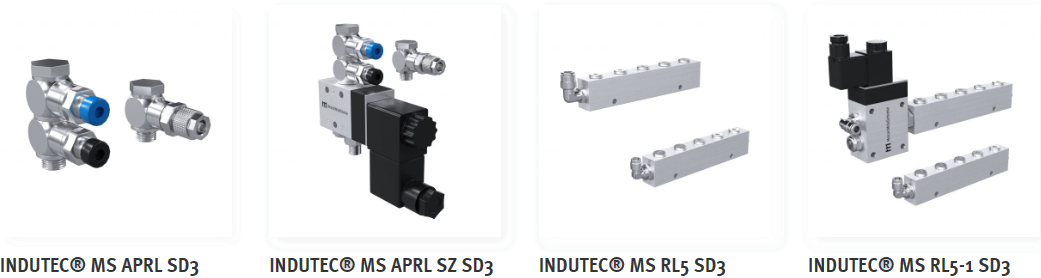

INDUTEC® MS Modular Systems / Series Rails (RL) for SD3

Series bars for INDUTEC® MS SD3 coaxial spray heads

The INDUTEC® MS system offers series rails for connecting one to five SD3 spray heads.

The spray air volume and medium volume can be adjusted directly on the INDUTEC® MS SD3 spray head.

INDUTEC® MS RL5-1 SD3 for connecting 1 to 5 spray heads in a single spray cycle, consisting of a series rail for spray and control air, including a solenoid valve and a series rail for the medium.

INDUTEC® MS RL5 SD3 for connecting 1 to 5 spray heads, each with its own spray cycle, consisting of a series rail for spray and control air and a series rail for the medium.

PRECISE DOSING OF MINIMAL MEDIUM QUANTITIES

The timing and duration of the spray cycle can be set on the valve unit. Regarding the power supply, you can choose between versions with 24V, 110V, and 230V.

MODULARLY EXPANDABLE

To supply multiple spray locations, a large number of valve units can be connected in parallel to the pressure vessel, and each spray station can be individually equipped with one or more coaxial spray heads.

PLACEMENT

Valve units can be placed anywhere. Connection kits and coaxial spray heads must be assembled separately and individually.

Series bars for INDUTEC® MS SD3 coaxial spray heads.

INDUTEC® MS Modular Systems / Pressure Vessel Units

FROM SMALL TO LARGE

Depending on the number of coaxial spray heads and valve units, as well as the choice of spray intervals and spray volume, a pressure vessel unit with the appropriate capacity must be selected.

Available tank capacities: 1, 2, 6, 10, 20, or 40 liters.

All pressure vessel units with a filling volume of up to 20 liters are standardly equipped with a potential-free level sensor. This way, if the filling level drops below the minimum level, a signal can be triggered to initiate automatic shutdown, an alarm, or similar actions.

A pneumatic agitator is also available as an accessory, ensuring constant medium viscosity.

STANDARD EQUIPMENT FOR ALL INDUTEC® MS PRESSURE VESSEL UNITS

>> Ready for connection to INDUTEC® MS valve units

>> Pressure regulator for setting vessel pressure, including hose

>> Air shut-off valve, including quick venting [INDUTEC® MS AV L]

>> TÜV safety valve (2.5/6 bar) [INDUTEC® MS SV2.5 / SV 6.0]

>> Medium outlet via riser pipe with check valve and filter

>> Lid opening for filling

>> Lid with adjustable ventilation for supplying a constant minimal amount of medium [INDUTEC® MS DEC]

>> Wall mount (for 1-6 liters)

>> Level monitoring from PVC (1 to 20 liters), potential-free, NC, contact-based [INDUTEC® MS FD…Ö PVC]

>> Operating pressure 2.5/4.0/6.0 bar (depending on version)

>> Removable pressure vessel

>> Ready for use